NEW

NEW

- installation

- RoHS

- REACH

- CE

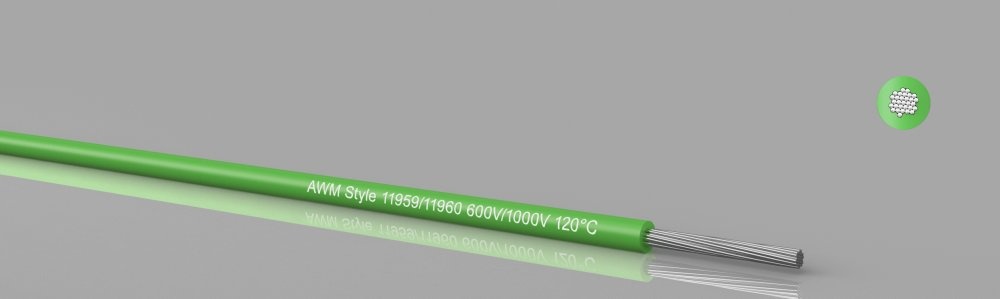

UL AWM Style 11959/11960

Application / Description

For internal wiring of electrical devices and control cabinets. Due to extremely thin wall thicknesses and a wide temperature range, it is an excellent alternative to wires with PVC, fluoropolymer or cross-linked insulation. The insulation material has good bending and flexing properties, excellent ageing characteristics and very good chemical resistance. The material is also flame-retardant and free of paint-wetting impairment substances.

Product range

| Order-No. | Dimension | Structure of conductor mm | O.D. approx. mm | weight kg/km | Cu-weigth kg/km |

|---|---|---|---|---|---|

| 7831265 | AWG 12/65 | 65x0,254 | 3,10 | 36,0 | 31,7 |

| 7831441 | AWG 14/41 | 41x0,254 | 2,65 | 23,0 | 20,0 |

| 7831641 | AWG 16/41 | 41x0,20 | 2,10 | 17,0 | 14,4 |

| 7831828 | AWG 18/28 | 18x0,20 | 1,85 | 10,0 | 8,5 |

| 7832018 | AWG 20/18 | 18x0,20 | 1,65 | 7,0 | 5,5 |

| 7832219 | AWG 22/19 | 19x0,16 | 1,45 | 5,0 | 3,7 |

| 7832407 | AWG 24/7 | 7x0,20 | 1,25 | 3,0 | 2,2 |

| 7832607 | AWG 26/7 | 7x0,16 | 1,10 | 2,0 | 1,4 |

| ▲ | compare | ||||

Construction / data

Conductor

- tinned stranded copper wire

Cross section

AWG

Core insulation

- TPE

Conductor resistance

Technical characteristics

Temperature range

- -40 °C to +120 °C

Bending radius static

- > 8 x O.D.

Bending radius dynamic

- > 13 x O.D.

Operating voltage

- 1.000 V

Testing voltage

- 6.000 V

Packaging

On RequestAdd-on information

Operating voltage per UL Style 11959 600 V, Style 11960 1000 V

Testing voltage per UL Style 11959 3500V, Style 11960 6000 V

Flammability: flame retardant acc. to HF (UL), FT-2 (cUL)

Temperature range cUL up to +125°C max. 20.000 hours